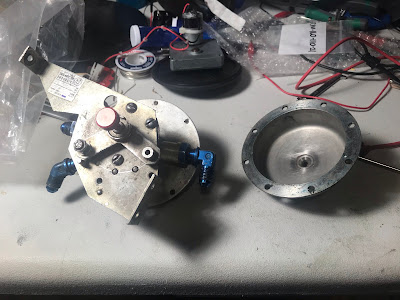

Some Pictures and Notes on Fuel Selector Valve

I started disassembling to ensure I understand what the function is. Fuel flows in through one of the three upper ports in the valve body. There is a four position rotary selector (with a ball detent) that rotates and also has a handle that pulls up through the center of the valve body and the selector.

If the handle is pulled up it pulls a spring loaded plunger up. This plunger seals off openings in the valve body and prevents fuel from flowing downward toward the discharge port. It also pulls a stopper away from the center opening in the bottom and allows fuel to flow out. This would be the "sumping" action of the valve.

If the handle is pushed down it relaxes the spring and allows fuel to flow downward while sealing off the opening in the bottom. Fuel can now flow from one of the three selectable inlet ports past the stopper and to the discharge port.

There are three AN fittings (0.165" internal fitting diameter which corresponds to a 1/4" - 4AN ) that can be selected. Each is sealed off with a ball check valve that prevents fuel from flowing inward. When the rotary selector is rotated to the proper position a finger that extends into the valve body pushes outward against the ball and this allows fuel to flow in from the selected port. One of the selectable positions puts the finger against a blank spot and thus no fuel can flow inward.

I pressed on one of the ball checks with a toad stabber and not much was pressure required to open it.

So a preliminary specification that works would be:

- one outlet port 4AN

- three inlet ports 4AN

- one drain port for hose fittings

- four position rotary selector (off, one, two, and three)

- ball checks in each inlet to prevent flow into the valve unless selected

- no check valve on the outlet port

It is plainly obvious why there are so many maintenance problems with this valve. There are many moving parts. Each inlet port has a snap ring, spring, and ball check. The selector finger has an arm, rotating barrel with upper and lower fingers, and retaining ring. The central sumping barrel has the barrel itself, upper and lower snap rings, plunger, rubber flapper, an o-ring, connecting lever, another o-ring, a knob, a roll pin, retaining clip, another snap ring. The selector handle is equipped with ball detents for the selector. So many parts it is rather complex.

It also appears that the valve is designed to fail. If the handle is pulled up it seals off fuel from flowing into the valve base from one of the selected ports. So why would any fuel flow out of the sump if there is no way for fresh fuel to get in?

I suspect the spring loading aspect allows fuel to flow as long as you don't pull up to far or too hard but it would be pretty easy for this to prevent any fuel from flowing. This would likely explain why many of these valves fill up with water and corrosion - it is actually looks like it would be easy to malfunction and prevent thorough sumping.

Comments

Post a Comment